Advantages of FRP Water Slide

FRP slide performance 1: The difference in corrosion resistance

Resin gives FRP Water Slide different corrosion resistance, allowing it to be used for extended periods in corrosive environments with various acids, alkalis, salts, and organic solvents.

FRP slide performance 2: Flame retardant

High-quality resin and flame retardant additives give the product excellent flame retardant performance. Generally, the oxygen index of flame retardant products is greater than 26, the flame diffusion coefficient is less than 25, and the smoke density is less than 500.

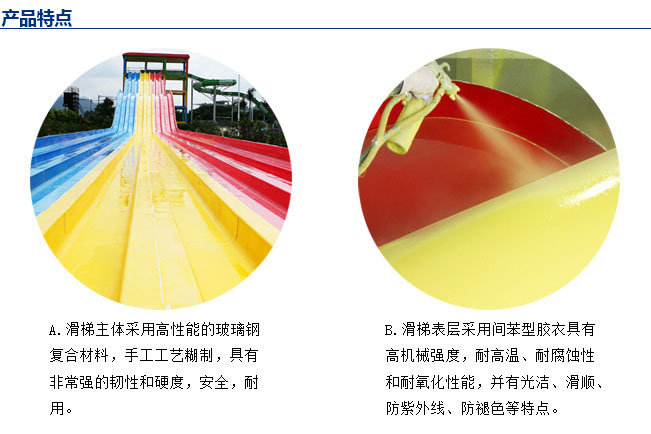

FRP slide performance 3: The perfect combination of lightweight and high-strength

Alkali-free glass fibre yarn and resin give the product unique lightweight and high-strength characteristics. The specific gravity of the product is one-fourth that of steel, making it suitable for various load-bearing structures in corrosive environments.

FRP slide performance 4: Anti-aging

The product is made of high-quality matrix resin and anti-aging additives, ensuring long-lasting anti-aging performance. It maintains long-term gloss and continuous high strength, with a service life exceeding 20 years.

FRP slide performance 5: Designability

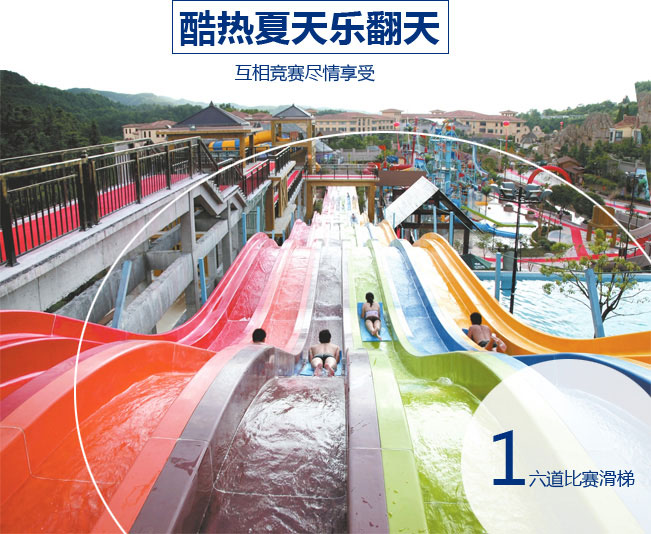

In addition to the flexible design performance of FRP Water Slide, the colour of the product can be customised according to customer requirements. The shape and size can also be cut and spliced to the customer’s desired dimensions.

FRP slide Properties 6: Safety slip

High elastic modulus and different surface effects of the grid provide non-slip properties. It is slightly elastic to reduce staff fatigue, with biplane, meniscus, sand surface, and diamond cover offering various anti-slip performances for different use occasions.

Glass fibre reinforced plastic slide performance 7:

Glass fibre and high-performance resin endow the product with superior electrical properties. The product’s penetration strength can reach 10kv/mm, and metal tools do not produce electricity or sparks when resisting. The product is non-magnetic and can be used safely in electromagnetic anti-explosive environments.

Related Post:

Advantages of FRP Water Slide

Advantages of Water Slide Rafting

Water Park Equipment Materials – The Difference Between FRP Slides and Inflatable Slides

Why Choose FRP Materials for Large Water Villages for Outdoor Water Park Equipment?