Water Park Equipment Materials – Introduction of FRP

Perhaps more and more customers will ask, what are the advantages of FRP products in water park equipment? Why should we choose to use FRP? FRP water park equipment will answer these customers:

1. Introduction of FRP

FRP is a kind of fibre-reinforced plastic. In professional terms, FRP is called composite material (the full name is fibre-reinforced resin composite material). FRP consists of three parts: one part is the gel coat, the second part is called the matrix, which is the resin (unsaturated polyester resin), and the other part is the reinforcing material – fibre cloth. The characteristics of FRP are 1. High strength and light weight; 2. Corrosion resistance; 3. Flame retardant; 4. Resistance to ageing, high temperature, etc. Its safety and excitement are definitely the first choice for FRP water park equipment.

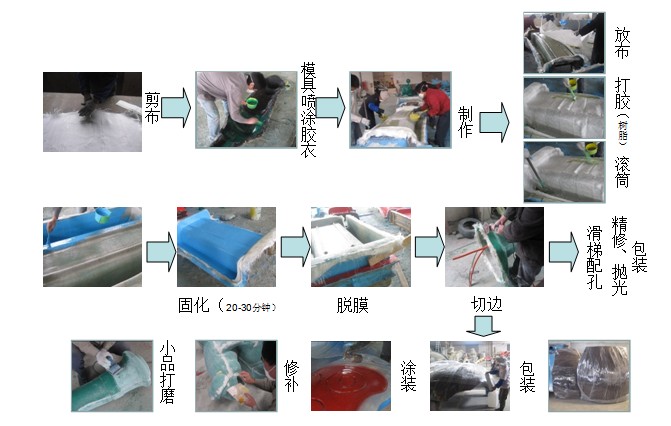

2. Process Flow of FRP

3. Introduction to Common Varieties of FRP Slides

A). FRP Slides

The gel coat used on the surface of the slide is 0.5mm thick, and the UV-resistant products of American Aslan Company are used. The resin is Changzhou Huarun 8200#, and the thickness of the product is 6-8MM. The surface of the product is smooth, the transition is smooth, the tensile strength of FRP is ≥78MPa (megapascal, the unit of pressure), the bending strength is ≥147MPa, and the modulus of elasticity is ≥7300MPa.

B). Water Spray Attraction

Play in the water sketches adopt a variety of cute cartoon shapes to produce water spray effects. There are also interactive amusement facilities that can be used as auxiliary equipment for the children’s pool in the water park. It is also a landscape decoration, adding a lively and interesting atmosphere. Playing in the water is also an essential Xerox equipment in the water park.

C). Water House

Water House, also known as water village and tree house, has been carefully combined and matched to meet tourists’ water exploration and amusement experience. It is a kind of interactive product that integrates various water toys, water buckets, water slides, and the theme landscape is equal to a comprehensive water amusement facility.

4. Advantages of FRP

a. Lightweight and High Strength: The relative density of FRP is between 1.5 and 2.0, which is only 1/4 to 1/5 of that of carbon steel, but the tensile strength is close to or even higher than that of carbon steel, and the specific strength is comparable to that of high-grade alloy steel. Therefore, it has excellent results in aviation, rockets, space vehicles, high-pressure vessels, and other products that need to reduce their own weight. The tensile, flexural and compressive strengths of some epoxy FRP can reach more than 400Mpa.

b. Good Corrosion Resistance: FRP is a good corrosion-resistant material, and it has good resistance to atmosphere, water and general concentrations of acids, alkalis, salts, and a variety of oils and solvents. It has been applied to all aspects of chemical corrosion protection, and is replacing carbon steel, stainless steel, wood, non-ferrous metals, etc.

c. Good Electrical Properties: It is an excellent insulating material, used to make insulators. It can still protect good dielectric properties under high frequency. It has good microwave permeability and has been widely used in radomes.

d. Good Thermal Performance: FRP has low thermal conductivity, 1.25~1.67kJ/(m·h·K) at room temperature, which is only 1/100~1/1000 of metal, and is an excellent thermal insulation material. It is an ideal thermal protection and ablation-resistant material in the instantaneous ultra-high temperature situation, which can protect the spacecraft from the erosion of high-speed airflow above 2000 ℃.

e. Good Designability: ①A variety of structural products can be flexibly designed according to needs to meet the requirements of use, and the product can have a good integrity. ②Materials can be fully selected to meet the performance of the product, such as: corrosion resistance, instantaneous high temperature resistance, high strength in a certain direction of the product, and good dielectric properties can be designed.

f. Excellent Manufacturability: ①The moulding process can be flexibly selected according to the shape, technical requirements, use and quantity of the product. ②The process is simple, it can be formed at one time, and the economic effect is outstanding, especially for products with complex shapes and small quantities that are not easy to form, and its process superiority is more prominent.

It is hoped that through the above information, customers can use FRP water park equipment with confidence. After all, the water park equipment is related to the lives of millions of tourists. The materials used are made by precision workmanship, and we dare not make defects.

Related Post:

Water park equipment materials-introduction of FRP

Matériel D’équipement De Parc Aquatique – Introduction De FRP

Water park equipment materials-the difference between FRP slides and inflatable slides

Why choose FRP materials for large water villages for outdoor water park equipment?